Introduction:

As a 3D printing enthusiast, I’m always on the lookout for new techniques that can simplify the process and improve the quality of the end product. In this post, I want to share with you a recent discovery that I believe can be a game-changer for many projects: heat-set inserts.

What are Heat-Set Inserts?

Heat-set inserts are small metal parts that can be easily added into thermoplastic materials such as PLA and PETG. They provide a threaded insert that allows for the easy attachment of screws or other components. They are particularly useful for creating strong, reliable joints in 3D printed parts.

Why Use Heat-Set Inserts?

In the past, creating threaded holes in 3D printed parts required tapping the material or using self-tapping screws, which can be time-consuming and often result in imperfect threads. Heat-set inserts provide a much simpler and more reliable solution. They allow for the creation of precise, high-quality threads that are resistant to stripping or other types of damage.

Where to Get Heat-Set Inserts?

There are many different types of heat-set inserts available on the market, but the particular ones I’ve been using were purchased from Amazon. They come in a pack of 100 and cost about $10.

Installation Process:

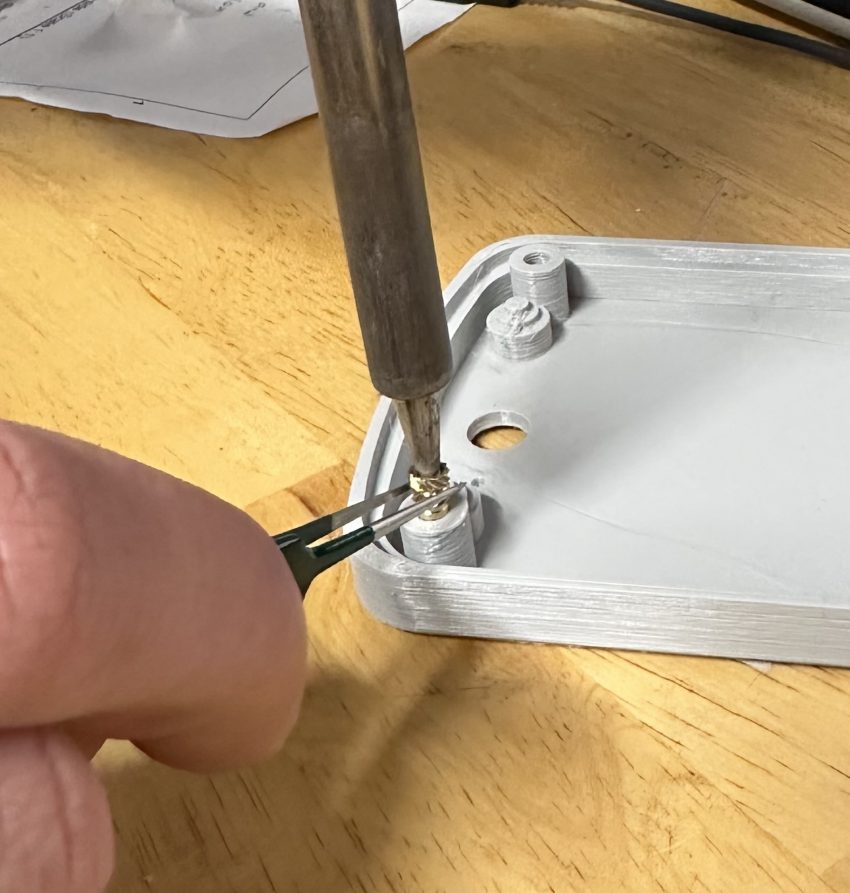

At first, I was a little unsure of how to install heat-set inserts, but I found that it’s actually quite easy. Simply hold the insert with tweezers and guide it into the thermoplastic material with a heated soldering iron. The heat from the soldering iron melts the plastic material slightly, allowing the insert to be pushed in smoothly. Once the insert cools down, it creates a secure and reliable threaded hole.

Conclusion:

If you’re a 3D printing enthusiast looking for a simple and reliable solution for creating threaded holes in your thermoplastic materials, I highly recommend trying out heat-set inserts. They’re inexpensive, easy to use, and can greatly simplify your projects. If you’re interested in trying them out, check out the Amazon link provided in the post.